Understanding Sublimation Printing

Sublimation printing involves transferring dye-based inks onto specially coated substrates using heat and pressure. The heat causes the ink to turn into a gas, which then permeates the surface of the blank material, resulting in a durable and vibrant image.

Key Factors for Successful Sublimation

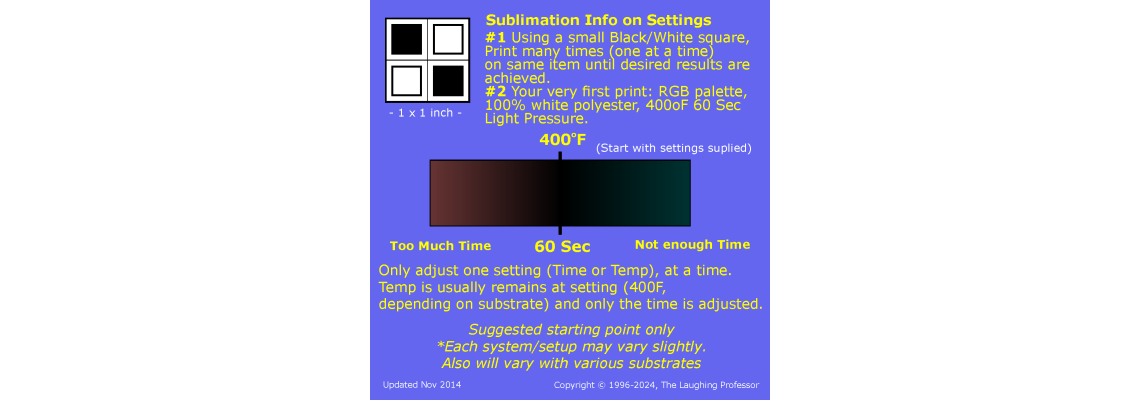

- Temperature: The heat press must reach a specific temperature to activate the sublimation inks.

- Time: The duration the heat press is applied affects the transfer quality.

- Pressure: Sufficient pressure ensures the ink penetrates the material properly.

Recommended Heat Press Settings for Common Sublimation Blanks

1. Polyester Fabric

- Temperature: 400°F (204°C)

- Time: 45-60 seconds

- Pressure: Medium

Polyester fabric is a popular choice for sublimation due to its smooth texture and ability to absorb dyes. Ensure your fabric is at least 65% polyester for best results.

2. Ceramic Mugs

- Temperature: 400°F (204°C)

- Time: 3-5 minutes

- Pressure: Medium

Mugs require a longer time to ensure the design adheres properly. Use a mug press or a wrap-around attachment for consistent results.

3. Metal Panels

- Temperature: 375-400°F (190-204°C)

- Time: 60-75 seconds

- Pressure: Medium

Metal panels provide a sleek and durable surface for sublimation. Ensure even pressure to avoid any warping.

4. Hardboard Coasters

- Temperature: 400°F (204°C)

- Time: 60 seconds

- Pressure: Medium

Hardboard coasters are ideal for creating personalized drinkware accessories. Pre-press the coasters for 5-10 seconds to remove any moisture.

5. Polyester-Coated Mouse Pads

- Temperature: 400°F (204°C)

- Time: 40-60 seconds

- Pressure: Medium

Mouse pads require a gentle yet consistent pressure to avoid any deformation. Ensure the coating is designed for sublimation.

6. Acrylic Blanks

- Temperature: 375°F (190°C)

- Time: 90 seconds

- Pressure: Light to Medium

Acrylic blanks offer a unique and glossy finish. Be cautious with the temperature to prevent warping.

7. Slate Photo Panels

- Temperature: 400°F (204°C)

- Time: 6-8 minutes

- Pressure: Medium

Slate photo panels are thicker and require longer pressing times to ensure the ink fully transfers.

8. Polyester-Coated Tiles

- Temperature: 400°F (204°C)

- Time: 6 minutes

- Pressure: Medium

Tiles provide a durable and vibrant surface for photos and designs. Ensure even pressure across the entire tile.

9. Polyester-Coated Glass

- Temperature: 400°F (204°C)

- Time: 4-6 minutes

- Pressure: Medium

Glass can be tricky due to its fragility. Gradually increase the pressure to avoid any breakage.

10. Neoprene Blanks

- Temperature: 400°F (204°C)

- Time: 50-60 seconds

- Pressure: Medium

Neoprene is commonly used for items like koozies and phone cases. Its flexibility makes it an excellent choice for sublimation.

Tips for Optimal Sublimation Results

- Pre-Pressing: Always pre-press your blanks for a few seconds to remove moisture and wrinkles.

- Protective Paper: Use parchment paper or a Teflon sheet to protect your heat press and prevent ink bleed.

- Test Prints: Conduct test prints on similar materials to fine-tune your settings.

- Consistent Pressure: Ensure your heat press provides even pressure across the entire surface of the blank.

Conclusion

Mastering the art of sublimation printing requires understanding the specific heat press settings for each type of blank. By following the recommended settings outlined in this guide, you can achieve vibrant, high-quality transfers on a variety of materials. Happy printing!

Feel free to share your experiences or ask any questions in the comments below. We’re here to help you create beautiful sublimation projects!

29 years of #TheProfessor

29 years of #TheProfessor

12% rewards for affiliate members

12% rewards for affiliate members

On-Page SEO Gold Seal

On-Page SEO Gold Seal

Leave a Comment