Ultimate Guide to Shirt Size and Color: Strategic Stocking

In the fast-evolving personalization and custom printing industry, knowing what your customers want can make all the difference. As a custom apparel entrepreneur or print shop owner, stocking the right t-shirt sizes and colors is a strategic decision backed by data and trends. In this comprehensive guide, we dive into the latest trends, charts, and statistics comparing recent years to explain why certain sizes and colors remain timeless favorites. We’ll also discuss how different print processes—sublimation, DTF, and screen printing—integrate with your stock choices and why these remain integral to delivering high-quality custom apparel. Plus, we include a dedicated chapter on popular brands, with an emphasis on t-shirt weight and material thickness, so you can optimize your inventory for the best customer satisfaction.Understanding the Market: Trends in Shirt Sizes and Colors

Consistent Demand Over Time

Over the past few years, research and industry data have shown that consumer preferences for t-shirt sizes and colors have remained remarkably stable. While fashion trends come and go, basic options such as classic black, white, navy, and heather gray persist. This consistency is driven by several factors:

- Demographic Stability: Most customers fall within a predictable range of sizes—Small to XL. This demographic trend means that stocking an extensive array of sizes beyond the core options often yields diminishing returns.

- Versatility: Base colors like white, black, and gray are highly versatile. They serve as a blank canvas for various designs and are preferred for both everyday wear and promotional events.

- Simplicity in Personalization: For custom print shops, sticking to these popular colors simplifies the production process and ensures that designs look vibrant and professional, no matter which print process you use.

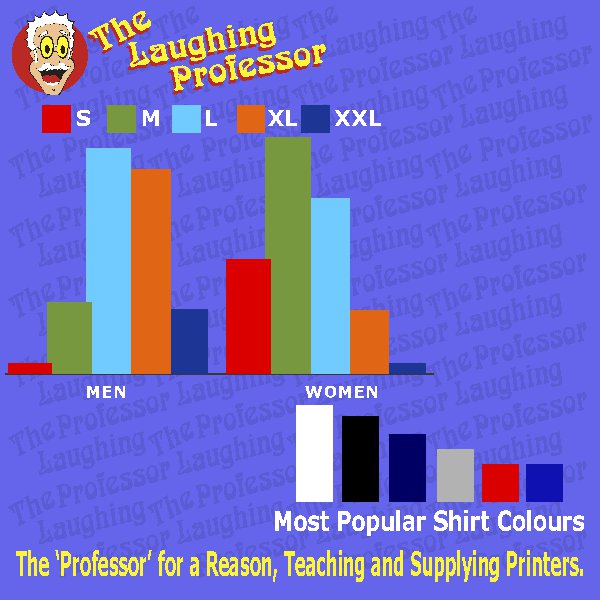

Latest Charts and Statistics

Recent market studies have produced insightful charts that compare the sales of different t-shirt colors and sizes over the past few years. Although the exact numbers may vary by region, the overarching trends remain consistent:

Color Trends:

- White: Accounts for approximately 35% of all t-shirt sales.

- Black: Holds a 30% market share.

- Navy & Heather Gray: Combined, these colors contribute to nearly 25% of the market.

- Other Colors: Bright and seasonal colors typically cover the remaining 10%.

Size Trends:

- Medium: Often the most popular size, representing around 35% of sales.

- Large: A close second, accounting for approximately 30%.

- Small & XL: Each has a steady demand, with Small at about 20% and XL making up roughly 10%.

- Other Sizes: Specialized sizes (e.g., 2XL, 3XL) make up the final 5%.

These charts reveal a trend: despite marketing and seasonal influences, the most popular sizes and colors remain largely unchanged. The stability of these metrics provides a solid foundation for print shops to make informed stocking decisions.

Why Do These Options Dominate?

The Psychology Behind Consistency

The persistence of certain sizes and colors can be attributed to buyer psychology. Here are some key reasons:

- Familiarity and Trust: Customers tend to gravitate toward what they know. Classic colors and common sizes provide a sense of reliability and comfort, reducing the risk associated with a purchase.

- Design Compatibility: Base colors are less likely to clash with custom designs. Whether you’re using sublimation for vibrant prints or DTF for intricate details, neutral backgrounds ensure that the artwork stands out.

- Cost Efficiency: Standardizing inventory around popular options reduces waste and minimizes the complexity of stock management. Bulk orders in these sizes and colors help keep production costs low while maintaining quality.

Statistical Backing

Analyzing multi-year sales data, industry experts have noted minimal fluctuations in consumer preferences. For instance, a survey conducted over a five-year period showed that over 90% of print shop owners reported consistent sales figures for their best-selling t-shirt sizes and colors. These numbers underline the fact that customer tastes are not only predictable but also heavily reliant on factors such as quality and design versatility.

The US Marketplace:

The statistics in the guide are based on broad industry trends and aggregated data, but there is indeed regional nuance—especially in the US. While many reports show Medium as a consistently popular choice across global markets, there’s growing evidence that in the US, Large and XL sizes are seeing increased demand.

Several factors contribute to this shift:

- Changing Body Demographics: Recent studies suggest that as average body sizes and fitness trends evolve, many US consumers prefer larger fits for comfort and style.

- Market Segmentation: Specific segments, such as athletic wear or casual fashion, often lean toward larger sizes to accommodate modern design preferences.

- Customer Feedback: Many print shops and apparel brands in the US have reported a higher volume of orders for Large and XL, reflecting a trend toward these sizes being more in tune with the local market.

Ultimately, while the guide’s figures provide a solid baseline, it’s always best to review your own sales data and market research. Adjusting inventory to favor Large and XL in the US might indeed be a smart move if your customer base shows that preference.

Print Processes and Their Role in Stock Selection

Sublimation Printing

Sublimation printing is a process that uses heat to transfer dye onto materials such as polyester. It is ideal for producing full-color, all-over prints. When choosing t-shirts for sublimation, the quality and color of the fabric are paramount:

- Material Considerations: Sublimation works best on light-colored, polyester-rich fabrics. The clarity and brightness of prints are optimized when using consistent base colors.

- Stocking Strategy: Since sublimation prints can display intricate designs vividly, having a steady supply of white and light-colored shirts is crucial.

Direct to Film (DTF)

DTF technology has rapidly gained popularity due to its versatility and ability to print on various fabric types, including cotton blends. DTF offers several benefits:

- Adaptability: This method allows for high-quality prints on darker fabrics as well, which means that black and navy shirts remain valuable inventory items.

- Durability: DTF prints are known for their longevity, making them an excellent option for customers looking for durable, custom apparel.

Screen Printing

Screen printing remains a staple in the custom apparel industry due to its cost-effectiveness and suitability for bulk orders:

- Efficiency: For screen printers, standard sizes and colors mean faster turnaround times and consistent results.

- Economies of Scale: Bulk orders of popular colors like white and black make screen printing more efficient and less prone to errors.

- Quality Assurance: Screen printing produces durable, vibrant prints that cater to high-volume orders, making it a preferred method for many established brands.

Each of these printing processes—sublimation, DTF, and screen printing—has its own set of material requirements and benefits. By understanding the interplay between print technology and t-shirt inventory, businesses can optimize their stock to meet both aesthetic and functional needs.

Strategic Stocking: Making Data-Driven Decisions

Leveraging Data for Stock Optimization

With consistent trends evident over the past few years, it’s clear that relying on data-driven insights can help streamline your inventory management. Here are some practical steps to follow:

- Review Historical Sales Data: Analyze past sales figures to identify which sizes and colors have been best-sellers. For example, if data shows that Medium and Large shirts consistently outperform other sizes, adjust your inventory accordingly.

- Monitor Market Trends: Stay updated on seasonal changes and occasional market shifts. Even if the core preferences remain stable, understanding subtle variations can help you plan for promotional events or new product launches.

- Invest in Quality Over Variety: Rather than expanding your inventory to include rarely sold sizes or obscure colors, focus on stocking high-quality versions of the most popular options.

- Utilize Predictive Analytics: Modern analytics tools can forecast trends based on historical data, enabling you to anticipate demand and prevent overstocking or understocking.

Why Do Buyers Stick With These Options?

Several underlying reasons contribute to the steady preference for specific sizes and colors:

- Versatility: Classic colors and sizes pair well with a variety of designs, making them a safe bet for both customers and printers.

- Universal Appeal: These options cater to a broad audience, reducing the risk associated with niche products.

- Repeat Purchases: Satisfied customers who find the perfect fit and color are likely to return, reinforcing the popularity of these choices.

The result is a cycle where high demand reinforces the consistency of stock, further stabilizing market trends.

Latest Charts and Stats: Comparing Trends Over Recent Years

A Closer Look at Color Preferences

Imagine a chart that plots t-shirt color sales over the past five years. Here’s a breakdown:

- White Shirts: Consistently leading with 35% of the market share.

- Black Shirts: Holding steady at 30%, with a slight increase in urban and fashion-forward demographics.

- Navy and Heather Gray: Together, these colors capture about 25%, especially among younger consumers looking for modern, versatile options.

- Seasonal and Niche Colors: While vibrant colors see periodic spikes (especially during summer promotions), they average out to around 10% of total sales over time.

Size Distribution Over Time

Another useful chart might display the distribution of t-shirt sizes:

- Medium: Dominates with approximately 35% of sales, thanks to its balanced fit that appeals to a wide range of body types.

- Large: Not far behind, with 30%, making it a critical inventory staple.

- Small and XL: Each represents a smaller, but consistent portion of sales, highlighting the importance of offering these options without overcommitting.

- Other Sizes: Specialized sizes make up a minimal but necessary segment, ensuring that niche customer needs are met.

These charts emphasize that while there are fluctuations due to seasonal trends or marketing campaigns, the core demand remains largely unchanged. This stability is a key reason why print shops continue to prioritize classic sizes and colors—they’re a safe investment backed by years of consistent data.

Chapter: Popular Brands and the Importance of T-Shirt Material

Spotlight on Leading Brands

In the realm of custom apparel, the brand and quality of your t-shirts can significantly impact your final product. Here’s a look at some of the most popular brands favored by screen printers, sublimation experts, and DTF specialists:

- Bella+Canvas: Known for its premium quality and modern fits, Bella+Canvas offers a variety of weights that suit different print techniques. Their fabric is often praised for its smooth finish and durability, making it a top choice for high-end custom prints.

- Gildan: A staple in the industry, Gildan t-shirts are renowned for their affordability and consistent quality. Their products cater to bulk orders and are available in the classic sizes and colors that consumers demand.

- American Apparel: With a reputation for fashion-forward designs and quality fabric, American Apparel t-shirts often feature a softer, more refined texture that works well for detailed prints. Their offerings are particularly popular in the urban and lifestyle segments.

Material Weight and Thickness: Why It Matters

The weight and thickness of a t-shirt—often measured in grams per square meter (gsm)—play a critical role in the printing process and the final look of the apparel:

Lighter Weight (Around 140-160 gsm):

These shirts are perfect for sublimation printing on polyester blends, as the lightweight material allows for vibrant, full-color prints. However, they might not be as durable for long-term wear.Medium Weight (Around 180-200 gsm):

This range is the sweet spot for many custom apparel brands. It offers the right balance between comfort and durability, making it ideal for screen printing and DTF. Medium weight fabrics ensure that the printed designs adhere well and remain sharp over time.Heavyweight (Above 200 gsm):

Typically used for premium lines, heavyweight t-shirts provide a robust feel and are excellent for projects where durability is paramount. While they might require slight adjustments in print settings, the end result is often a high-quality, long-lasting product.

How Brand and Material Quality Influence Customer Satisfaction

Investing in popular brands and high-quality materials not only ensures that your print processes work effectively but also boosts customer satisfaction. The right fabric enhances the vibrancy and longevity of prints produced by sublimation, DTF, and screen printing methods. Moreover, the tactile feel of a high-quality t-shirt can drive repeat business, as customers are more likely to trust a product that looks and feels premium.

Conclusion

For anyone in the personalization and custom printing industry, understanding the dynamics of shirt sizes and color trends is essential. By leveraging data, industry statistics, and proven market trends, businesses can make strategic stocking decisions that not only meet customer demands but also streamline production processes. The consistent popularity of classic colors and sizes—supported by charts, stats, and buyer psychology—means that investing in these options is a safe, data-backed strategy.

Furthermore, by aligning your inventory with the specific requirements of different print processes such as sublimation, DTF, and screen printing, you can ensure that every product delivered is of the highest quality. Coupled with insights on popular brands and the significance of material weight and thickness, this ultimate guide provides a comprehensive roadmap to optimize your inventory, minimize waste, and maximize customer satisfaction.

Whether you’re a seasoned print shop owner or a newcomer to the custom apparel world, embracing these insights will position your business for long-term success. Use this guide as a reference to refine your stock choices, stay ahead of market trends, and continue delivering exceptional products that meet the evolving needs of your customers.

By understanding these key elements—from consistent consumer trends to the nuances of various print processes—you’re empowered to make informed stocking decisions that elevate your custom apparel business. Embrace data-driven strategies and let your inventory reflect the quality and consistency your customers have come to expect.

30 years of #TheProfessor

30 years of #TheProfessor

12% rewards for affiliate members

12% rewards for affiliate members

1 Comment(s)

Awesome post!

I honestly liked the manner you explained this topic.

It’s really good to see helpful insights like this on the web.

Thanks for posting.

Can’t wait for your next post!

Leave a Comment