1. Use High-Resolution Images

Why High Resolution Matters

High-resolution images are crucial in dye sublimation printing because they ensure that your final print is sharp and detailed. Low-resolution images can appear pixelated and blurry when enlarged, detracting from the overall quality of the print.

Recommended Resolution

For the best results, aim for a resolution of at least 300 DPI (dots per inch). This will help maintain the clarity and detail of your design, especially when printing larger items like banners or apparel.

Preparing Your Images

- Check Image Quality: Before starting your design, verify the resolution and quality of your images. Use photo editing software to enhance and resize images if necessary.

- Vector Graphics: Whenever possible, use vector graphics (such as those created in Adobe Illustrator) because they can be scaled infinitely without losing quality.

2. Consider Color Limitations

Understanding Sublimation Ink

Dye sublimation printing uses a specific type of ink that turns into gas when heated and bonds with the polymer-coated substrate. This process can affect how colors appear, especially when dealing with whites and light colors.

White and Light Colors

- White Areas: Dye sublimation printing does not print white ink. Any white areas in your design will remain the color of the substrate. For example, if you’re printing on a colored or patterned substrate, these areas will show through.

- Design Adjustments: To address this, either use the substrate color to your advantage or ensure your design covers all areas that need to be white with another color that will print effectively.

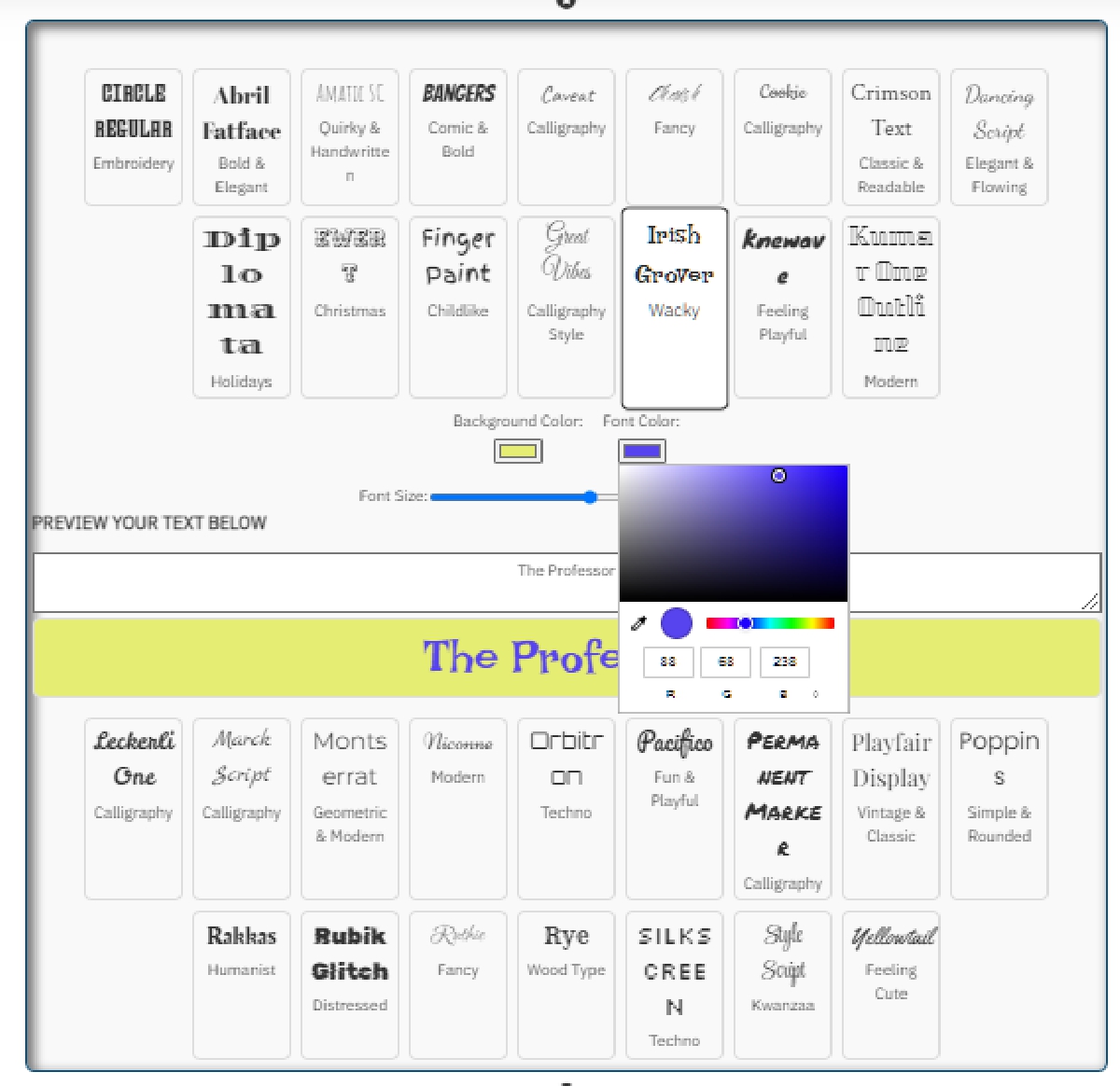

Color Profiles

- Use Correct Profiles: Use the color profiles recommended by your printer manufacturer. This ensures that the colors you see on your screen are as close as possible to what will be printed.

- Soft Proofing: Utilize soft proofing in your design software to simulate how the colors will appear on the final print.

3. Avoid Intricate Details

Detail Translation

While dye sublimation can produce detailed prints, extremely intricate details may not translate well due to the nature of the printing process and the materials used.

Simplifying Your Design

- Bolder Elements: Opt for bolder, more straightforward design elements that will remain clear and legible after printing.

- Test Prints: Conduct test prints to see how fine details are rendered. This can help you make necessary adjustments before committing to the final print run.

Line Thickness

- Minimum Thickness: Ensure that lines and small elements have a minimum thickness of 1-2 pixels to ensure they are visible and clear on the final print.

Conclusion

Designing for dye sublimation printing requires attention to detail and an understanding of the printing process. By using high-resolution images, considering color limitations, and avoiding overly intricate details, you can create beautiful, vibrant prints that stand out. Always test your designs and make adjustments as needed to achieve the best possible results.

With these tips in mind, you'll be well on your way to mastering dye sublimation printing and producing stunning, high-quality prints. Happy designing!

Happy printing!Feel free to share your experiences or ask any questions in the comments below. We’re here to help you create beautiful sublimation projects!

30 years of #TheProfessor

30 years of #TheProfessor

12% rewards for affiliate members

12% rewards for affiliate members

Leave a Comment