16 Jul

Posted By

0 Comment(s)

3455 View(s)

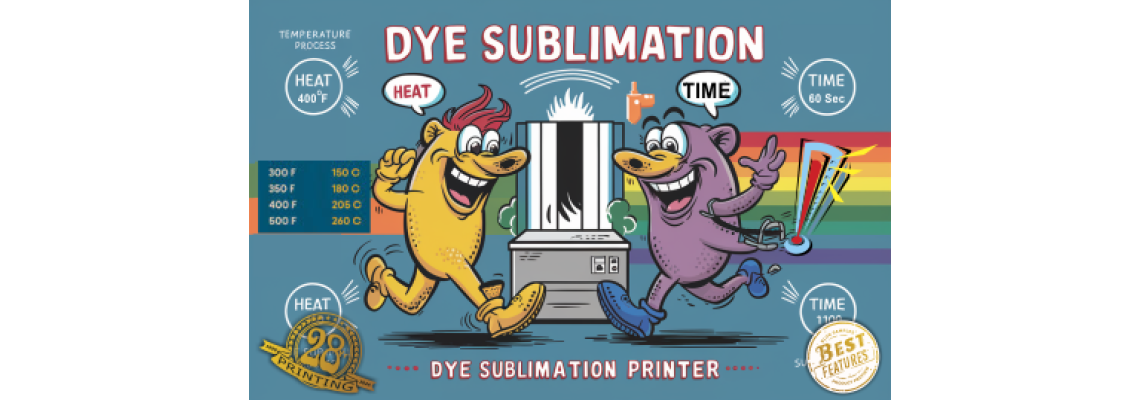

The following chart should only serve as a starting place.

Getting quality end products is a result of practice, smart color management, following the manufacturers guidelines and more practice. more can be found here on setting up time / temp to reduce mis-printed products. I've added a 'PRINT page' button at the bottom, for your convenience.I put this together in 2018, if you would like to add or update something please comment below.

Surface | Press Time | Temp | Pressure | Tips / Comments |

|---|---|---|---|---|

Soft L'ink T-shirts | 35-40 secs | 400°F | 40 psi (Medium) | Pre-press shirts for 3-5 secs to eliminate moisture. use blow-out sheet to prevent ghosting. |

Microfiber | 40 secs | 400°F | 40 psi (Medium) | |

Vapor Apparel | 50-55 secs | 390°F | 40 psi (Medium) | See vaporapparel.com for tips on reducing press lines. |

Polyester Mouse pads | 45 secs | 400°F | 40 psi (Medium) | Look for a tight knit and high white point for more brilliant color |

Subli-Flock | 50 secs | 340°F | 40 psi (Medium) | Check out Specialty Materials |

Metal (unisub) | 60 secs | 400°F | 40 psi (Medium) | Use blow-out paper, Remove plastic coating before pressing |

| -Standard Metal Door Keys | 60 secs | 400°F | 40 psi (Medium) | |

Metal (other) White, Silver, Bronze | 60 secs | 375°F-400°F | 40 psi (Medium) | |

Lighters (Metal windproof) | 70 secs | 400°F | 40 psi (Medium) | |

Wrist Watches | 60 secs | 400°F | 40 psi (Medium) | |

Travel Mugs | 50 secs | 400°F | 40 psi (Medium) | |

Unisub Products | 60 secs | 400°F | 40 psi (Medium) | Remove plastic coating, tear transfer paper away immediately after pressing. |

FR Plastics | 60-75 secs

| 400°F | Medium

| Remove plastic coating, tear transfer paper away immediately after pressing. |

Kids Spoons & Cutlery/silverwear | 50 secs | 400°F | Medium-Heavy | |

Pens | 15-20 secs | 320°F | Light | |

Sunglasses | 40 secs | 340°F | Medium-Heavy | |

Dominoes | 50 secs | 400°F | Medium-Heavy | |

Calculator | 30 secs | 360°F | Medium | |

Ceramic Mugs | 150-210 secs | 350-400°F | 40 psi (Medium) | |

-Mugs 11oz | 180 secs | 385°F | ||

Ceramic & Glass Tiles | 300-720 sec | 400°F | 40 psi (Medium) | Press tiles from the back (transfer side down) press into silicone pad |

Slate | 420 secs | 400°F | ||

Sublimation Film | 30-60 secs | 350°F-400°F | 40 psi (Medium) | |

Reveal | 30 secs | 375°F | ||

Subli-Cotton | 30 secs | 375°F | ||

Subliwrap | 120 secs | 356°F | ||

Subli-Clear | 30 secs | 350°F | Warm Peel | |

Oracal 652 | 30 secs | 350°F | Warm Peel | |

Nylon (melting point 374°F) | 30-50 secs | 340°F | ||

HTV | 15 sec | 320°F | ||

| * Silicone rubber sponge replacement platen cover 0.375" thick * Heat conductive rubber pad green 0.125" thick : red 0.625" thick for wraps * Nomex felt pad white 1/8 thick heat resistant cushion. | ||||

Feel free to reach out if you have any questions or need further assistance with your dye sublimation printing projects.

30 years of #TheProfessor

30 years of #TheProfessor

12% rewards for affiliate members

12% rewards for affiliate members

Leave a Comment